Friday, December 27, 2013

DC 1 3V to 22V Adjustable Regulator

But what if you want a voltage output that does not fit into one of the standard ranges or if you want to be able to easily adjust this output voltage? The MiniReg is the answer: it can be set to provide the exact voltage you require. It is based on an LM317T 3-terminal regulator. The PCB has only a few other components: three diodes, three capacitors, two resistors and a trimpot to set the output voltage from the regulator.

|

| DC 1.3V to 22V Power Supply Circuit Diagram |

Diagram shows the circuit details. The LM317T adjustable regulator provides a nominal 1.25V between its OUT and ADJ (adjust) terminals. The output voltage from REG1 is set by the 110O resistor (R1) between the OUT and ADJ terminals and by the resistance between the ADJ terminal and ground. This works as follows: by using a 110O resistor and assuming an exact 1.25V reference, the current flow is set at 11.36mA. This is calculated by dividing the voltage between the OUT and ADJ terminals (1.25V) by the 110O resistor.

This current also flows through trimpot VR1. This means that if VR1 is set to a value of 1kO , then the voltage across this resistor will be 1kO x 11.36mA or 11.36V. This voltage is then added to the 1.25V reference to derive the output voltage ñ in this case 12.61V. In practice, the current flow out of the ADJ terminal also contributes slightly to the final output voltage. This current is of the order of 100µA. So if VR1 is set to 1kO , this can add 0.1V to the output, ie, we get 12.71V.

If you are interested in the output voltage equation, then it is:

VOUT = VREF(1 + R1/R2) + IADJ x R2

where VOUT is the output voltage, VREF is the voltage between the OUT and ADJ terminals and IADJ is the current out of the ADJ terminal (typically 50µA but as high as 100µA). R1 is the resistance between the OUT and ADJ terminals, while R2 is the resistance between the ADJ terminal and ground. Diode D1 in series with the input provides reverse polarity protection. This means that if you connect the supply voltage around the wrong way, you cannot do any damage.

Diode D2 protects the regulator if the input becomes shorted to ground while it is powered up. Without D2, current would attempt to flow back from the output capacitor through the regulator to the shorted input and that could kill it. But D2 becomes forward biased and conducts, effectively preventing any reverse current flow through REG1.

Diode D3 is also included to protect REG1. It does this by clamping the voltage between the ADJ terminal and the OUT & IN terminals in the event that one of the latter is shorted to ground. Finally, capacitors C1 & C2 reduce ripple and noise by bypassing the IN (input) and ADJ terminals respectively. C3 prevents regulator oscillation by swamping any low-value capacitance that may be connected to this output.

- Source

- SiliconChip

Thursday, December 26, 2013

USB Powered Audio Power Amplifier

USB Powered Audio Power Amplifier Circuit diagram:

Wednesday, December 25, 2013

Sub Woofer and Controller Circuit Diagram

all of sub woofers use a immense speaker driver in a immense box, with tuning vents & all the difficulties (& vagaries) that conventional operation entails. By conventional, I mean that the speaker & cabinet are operated as a resonant technique, using the Thistle-Small parameters to get a box which will (if everything works as it ought to) provide excellent performance.

The check methods I used are applicable to any combination, but in general I recommend either a single giant driver or a pair of (say) 300mm units. The next hurdle is the amplifier needed to drive the speaker. This is not trivial. If the selected driver has a sensitivity of 93dB / W @ one metre, then you can safely assume that the efficiency will be less than this below resonance, by a factor of possibly 6dB or more. In case you are used to driving a sub with 100W, this means that you have increased the power to 400W - although this is an over-simplification.

If they are to operate the sub from 60Hz (my aim from the outset), they will increase the power by 12dB for each octave, so if 20W is necessary at 60Hz, then at 30Hz this has increased to 320W, & at 15Hz, you will require over 5kW.

Fortunately, the reality is a tiny different, & 400W or so will be over sufficient for a powerful process, due chiefly to the fact that the energy content in the low bass region is not normally all that great. (Although some program material may have high energy content, in general this is not the case). The EAS process augments the existing process, which is allowed to roll off naturally - contrast this with the normal case, where a crossover is used to separate the low bass from the main process, so existing speaker capability is lost.

The controller is (actually very) simple, & the circuit is shown in Figure one. An input buffer ensures that the input impedance of the source does not affect the integrator performance, & allows summing of left & right channels without any crosstalk. The output provides a phase reversal switch, so that the sub can be properly phased to the remainder of the process. If the mid-bass disappears as you advance the level control, then the phase is wrong, so switch to the opposite position.

The integrators (U1B & U2A) include shelving resistors (R6 & R9), & the capacitor / resistor networks (C1-R4, C3-R7) be positive that signals below 20Hz are attenuated. In case you dont require to go that low, then the worth of the caps (or the resistors R4 & R7) can be reduced. I used four.7uF caps, & these are non-polarized electrolytic - a high value was needed to keep the impedance low to the integrators. I originally included the dual pot (VR1) to permit the upper frequency roll off to be set - however it does no such thing (as described above). The final output level is set with VR2, which may be left out if your power amp has a level control.

The unity gain range (using a 20k pot as shown) is from 53Hz to 159Hz. This ought to be sufficient for most systems, but if desired, the resistors (R5 & R8) can be increased in value to 22k, or you can select a bigger value pot. Using 22k resistors & the 20k pot will give a range from 36Hz to 72Hz.

The input must be a standard full range (or for a stampeded method, the whole low frequency signal). Do not use a crossover or other filter before the EAS controller. For final modification, and to integrate the method in to your listening room, I recommend the constant-Q equalizer. The final result using this is extraordinarily nice - I have flat in-room response to 20Hz!

The EAS method is surprisingly simple to set up with no instrumentation. Of coursework in case you have an SPL meter & oscillator you can also confirm the settings with measurements. Keep in mind that the room acoustics will play havoc with the results, so unless you require to drag the whole method outside, setting by ear might be the simplest. Even in case you did get it exactly right in an anechoic surroundings, this would alter one time it was in your listening room anyway.

It takes a small experimentation to get right, but is surprisingly simple to do. When properly set, a check track (or bass guitar) ought to be smooth from the highest bass note to the lowest, with no gross peaks or dips. Some are inevitable because of room resonances & the like, but you will discover a setting that sounds "right" with small difficulty.

I measured 80dB SPL at one meter in my workshop (sub-woofer perched on a chair in more or less the middle of the space) with at 25Hz & 70W. This improved dramatically when the unit was installed in the listening room, but as I said earlier, there is usually not a lot recorded below around 35Hz. The longest pipe on the organ is usually about 16Hz, but larger pipes still may be used. It was found necessary to cease group of diapasons (able to 8Hz) in the famous Sydney Town Hall organ because when they were used, the very low frequency caused building destroy.

Tuesday, December 24, 2013

Simple Solar Cell Voltage Regulator Circuit Diagram

Sunday, December 22, 2013

Miniature USB Powered Amplifier for Laptops

A USB port delivers maximum 500mA current and at 5Volts, it comes to max 0.5×5=2.5Watts. So, if our circuit eats 0.5-1Watts power, only 1.5Watt is left for speakers output. Now you might ask 1.5watt wouldn’t create much sound. But believe me, under good conditions, this 1.5Watts is much more than expected. And this time we are going to use 0.5Watt-4Ohm x 2nos speakers.

These speakers are flat type having magnet inside them, and available at wholesale electronics shop in around 30rs per piece. For speaker box, use old jumbo matches box like homelite box. And for circuit, you need is an audio amplifier circuit capable of giving 0.5Watt output at each channel.

Here we will use a general purpose stereo amplifier TDA2822M IC, which comes in 8pin DIP package and usually found in mini walk-mans, etc. This IC can give up to 450 mW/channel with 4-ohm loudspeaker at 5V supply which is near our requirement.

The datasheet of TDA2822M can be downloaded in PDF format here (PDF, 362KB). The expense in making this circuit is no more than 25 rupees. Hence the total cost becomes 30+30+25=85rupees, and if we add the cost of wires, jacks etc then it well fits under 100rupees. It’s a very cheap solution when USB speakers in market costs more than 300 rupees.

Saturday, December 21, 2013

The signal jammer is what increases the signal

The signal the external antenna picks up is sent over wires to the signal jammer. The signal jammer is what increases the signal. Your boosted signal is then sent to the internal antenna which wirelessly rebroadcasts a more powerful signal within your space.

Cell blocker operate on different frequencies: 800 MHz, 1900 MHz and iDEN. The 800MHz frequency is compatible with Verizon phones outside of Florida and Texas, Alltel phones in selected states, and US Cellular phones in selected states. T-mobile, Sprint, Metro PCS and several other carries operate on the 1900MHz band. AT&T operates on both bands.

Often the most comprehensive solution is to opt for a Dual Band Cellular jammer. These blocker operate on both the 800 MHz and 1900 MHz bands, ensuring proper coverage with all major carriers. Nextel users in need of a cellular jammer must invest in an iDEN jammer.

Whether you need to amplify cellular signals in a large home, small apartment, warehouse or car, there are cell blocker that are designed for your needs. The following blocker are extremely popular in the cell jammer space and represent some of the different applications for cellular blocker.

One of the most popular cell jammer kits on the market, the YX545 Cellular jammer Kit is dual band, making it compatible with all cell phone carriers except Nextel. This cell jammer can amplify cellular signals in an area of 2,500-3,000 square feet with a 60dB gain, making it ideal for small home and office settings. The YX545 kit features everything you need for set-up and installation, including all the necessary cables and antennae.

The 841262 Dual Band jammer from Wilson Electronics is comparable to the YX545. However, this model amplifies cellular signals up to 5,000 square feet with a slightly higher 62 dB gain. Thus the Wilson 841262 is optimal for application in medium-to-large offices or homes. The standard external antenna, jammer and internal antenna setup applies.

The Wilson Sleek is a unique cell jammer in that it doesnt include a visible internal antenna or a separate jammer component. Designed for use while on-the-go, this cell jammer from Wilson Electronics is simply a cell phone cradle that has an internal antenna built right in.

Friday, December 20, 2013

Linear RF Power Meter

If the voltage on pin A1 is less than 0.8 V, the IC enters the shutdown mode and draws a current of only a few microampères. The LMV225 can be switched between the active and shutdown states using a logic-level signal if the signal is connected to the signal via the 10-kR resistor.

Circuit diagram:

The supply voltage, which can lie between +2.7 V und +5.5 V, is filtered by a 100nF capacitor that diverts residual RF signals to ground. Finally, there is an output capacitor that forms a low-pass filter in combination with the internal circuitry of the LMV225. If this capacitor has a value of 1 nF, the corner frequency of this low-pass filter is approximately 8 kHz. The corner frequency can be calculated using the formula fc = 1 ÷ (2 p COUT Ro) where Ro is the internal output impedance (19.8 k?). The output low-pass filter determines which AM modulation components are passed by the detector.

The output, which has a relatively high impedance, provides an output voltage that is proportional to the signal power, with a slope of 40 mV/dB. The output is 2.0 V at 9 dBm and 0.4 V at –40 dBm. A level of 0 dBm corresponds to a power of 1 mW in 50 R. For a sinusoidal wave-form, this is equivalent to an effective voltage of 224 mV. For modulated signals, the relationship between power and voltage is generally different.

The table shows several examples of power levels and voltages for sinusoidal signals. The input impedance of the LMV225 detector is around 50 R to provide a good match to the characteristic impedance commonly used in RF circuits.

The data sheet for the LMV225 shows how the 40-dB measurement range can be shifted to a higher power level using a series input resistor. The LMV225 was originally designed for use in mobile telephones, so it comes in a tiny SMD package with dimensions of only around 1 × 1 mm with four solder bumps (similar to a ball-grid array package). The connections are labelled A1, A2, B1 and B1, like the elements of a matrix. The corner next to A1 is bevelled.

Copyright: Elektor Electronics

Thursday, December 19, 2013

Modular Headphone Amplifier

P1___________47K Log. Potentiometer (twin concentric-spindle dual gang for stereo)

R1___________4K7 1/4W Resistor

R2___________12K 1/4W Resistor

R3,R4________33R 1/4W Resistors

R5,R6________4R7 1/4W Resistors

C1___________1µF 63V Polyester Capacitor

C2,C5________100nF 63V Polyester Capacitors

C3,C6________22µF 25V Electrolytic Capacitors

C4,C7________2200µF 25V Electrolytic Capacitors

IC1__________NE5532 Low noise Dual Op-amp

IC2__________78L09 9V 100mA Positive Regulator IC

IC3__________79L09 9V 100mA Negative Regulator IC

D1,D2_______1N4002 200V 1A Diodes

J1,J2________RCA audio input sockets

J3,J4________6mm. or 3mm. Stereo Jack sockets

J5___________Mini DC Power Socket

Notes:

- The circuit diagram shows the Left channel only and the power supply.

- Some parts are in common to both channels and must not be doubled. These parts are: P1 (if a twin concentric-spindle dual gang potentiometer is used), IC2, IC3, C2, C3, C4, C5, C6, C7, D1, D2, J3, J4 and J5.

- This module requires an external 15 - 18V ac (100mA minimum) Power Supply Adaptor.

Output power (1KHz sinewave):

32 Ohm: 140mW RMS

Sensitivity:

275mV input for 1V RMS output into 32 Ohm load (31mW)

584mV input for 2.12V RMS output into 32 Ohm load (140mW)

Frequency response @ 2V RMS:

Flat from 15Hz to 23KHz

Total harmonic distortion into 32 Ohm load @ 1KHz:

1V RMS and 2V RMS 0.0012%

Total harmonic distortion into 32 Ohm load @ 10KHz:

1V RMS and 2V RMS 0.0008%

Tuesday, December 17, 2013

Simple Nicad Battery Charger

This simple charger uses a single transistor as a constant current source. The voltage across the pair of 1N4148 diodes biases the base of the BD140 medium power transistor. The base - emitter voltage of the transistor and the forward voltage drop across the diodes are relatively stable. The charging current is approximately 15mA or 45mA with the switch closed. This suits most 1.5V and 9V rechargeable batteries. The transformer should have a secondary rating of 12V ac at 0.5amp, the primary should be 220/240volts for Europe or 120volts ac for North America.

Simple Nicad Battery Charger Circuit diagram :

WARNING: Take care with this circuit. Use a voltmeter to observe correct polarity. Nicads can explode if short circuited or connected with the wrong polarity.

Wednesday, October 9, 2013

Reducing Relay Power Consumption

In this respect the relay shown has specifications of 3.5 and 1.5V respectively, yet the circuit allows it to operate from an intermediate supply voltage of 2.5V. Table 1 compares the relay’s power dissipation with fixed operating voltages across it, and with the circuit shown here in place. The power savings are significant. When SW1 is closed, current flows through the relay coil, and C1 and C2 begin to charge. The relay remains inactive because the supply voltage is less than its pickup voltage. The RC time constants are such that C1 charges almost completely before the voltage across C2 reaches the logic threshold of the analogue switch inside the MAX4624 IC.

When C2 reaches that threshold, the on-chip switch connects C1 in series with the 2.5V supply and the relay coil. This action causes the relay to be turned on because its coil voltage is then raised to 5 V, i.e., twice the supply voltage. As C1 discharges through the coil, the coil voltage drops back to 2.5 V minus the drop across D1. However, the relay remains on because the resultant voltage is still above the dropout level (1.5 V). Component values for this circuit depend on the relay characteristics and the supply voltage. The value of R1, which protects the analogue switch from the initial current surge through C1, should be sufficiently small to allow C1 to charge rapidly, but large enough to prevent the surge current from exceeding the specified peak current for the analogue switch.

The switch’s peak current (U1) is 400mA, and the peak surge current is IPEAK = (VIN – VD1) / R1 + RON) where RON is the on-resistance of the analogue switch (typically 1.2 Ω). The value of C1 will depend on the relay characteristics and on the difference between VIN and the pickup voltage. Relays that need more turn-on time requires larger values for C1. The values for R2 and C2 are selected to allow C1 to charge almost completely before C2’s voltage reaches the logic threshold of the analogue switch. In this case, the time constant R2C2 is about seven times C1(R1 + RON). Larger time constants increase the delay between switch closure and relay activation. The switches in the MAX4624 are described as ‘guaranteed break before make’. The opposite function, ‘make-before break’ is available from the MAX4625. The full datasheets of these interesting ICs may be found at http://pdfserv.maxim-ic.com/arpdf/MAX4624-MAX4625.pdf

Tuesday, October 8, 2013

VW CAR PASSAT ENGINE CONTROL AND AUTOMATIC SOLENOID ELECTRICAL WIRING CIRCUIT

1993 VW Passat Engine Control Module, Automatic Control Unit, and Automatic Solenoid Electrical Wiring Diagram are shown in the following figure. It shows the connection and wiring between each parts and component of Engine Control Module, Automatic Control Unit, and Automatic Solenoid system of the vehicle such as the multi-function switch, fuse/relay panel, knock sensor, coolant temperature sensor, shift lock solenoid, starter interlock/back up lit relay,automatic control computer clutch shut off relay, automatic control unit, automatic solenoids, program switch, throttle position sensor, full throttle switch, idle switch, throttle valve potentiometer, ignition booster, distributor firing order, engine control module, carbon canister, cold starter, idle air control valve, evap emission on/off valve, and many more.

Monday, October 7, 2013

Multi Sound For Guitars

These two individual coils are usually interconnected with fixed wiring so that they are always used in series. The circuit proposed here offers the possibility of using a hum-bucker with four connections in no less than four different modes, each of which having its own sound. The only things that have to be changed on the guitar are the wiring and the addition of a four-position switch. The latter requires drilling holes in the guitar of course, but if there is a control cover plate (along the lines of a Fender Stratocaster, for example) then it makes sense to put the switch there. This avoids the need for drilling holes in the wood while keeping an (expensive) guitar reasonably unmarred. The schematic shows what the various things look like, electrically speaking, before and after the multisound modification.

These two individual coils are usually interconnected with fixed wiring so that they are always used in series. The circuit proposed here offers the possibility of using a hum-bucker with four connections in no less than four different modes, each of which having its own sound. The only things that have to be changed on the guitar are the wiring and the addition of a four-position switch. The latter requires drilling holes in the guitar of course, but if there is a control cover plate (along the lines of a Fender Stratocaster, for example) then it makes sense to put the switch there. This avoids the need for drilling holes in the wood while keeping an (expensive) guitar reasonably unmarred. The schematic shows what the various things look like, electrically speaking, before and after the multisound modification.Saturday, October 5, 2013

Battery Switch With Low Dropout Regulator

The IC will switch over to the backup battery when it detects that the pass transistor for the main voltage input is in danger of no longer being able to maintain the required output voltage. The device then smoothly switches over to the backup battery. The open-drain status output BACKUP goes low to indicate when this has occurred. When neither battery is able to maintain the output voltage at the desired level the open-drain output DROPOUT goes low. The LT1579 can operate with input voltages of up to +20 V from the batteries. The regulator output OUT is short-circuit proof. The shutdown input switches off the output; if this feature is not required, the input can simply be left open.

The IC will switch over to the backup battery when it detects that the pass transistor for the main voltage input is in danger of no longer being able to maintain the required output voltage. The device then smoothly switches over to the backup battery. The open-drain status output BACKUP goes low to indicate when this has occurred. When neither battery is able to maintain the output voltage at the desired level the open-drain output DROPOUT goes low. The LT1579 can operate with input voltages of up to +20 V from the batteries. The regulator output OUT is short-circuit proof. The shutdown input switches off the output; if this feature is not required, the input can simply be left open.Friday, October 4, 2013

Moduler Audio Preamplifier

High Quality, Discrete Components Design, Input and Tone Control Modules

To complement the 60 Watt MosFet Audio Amplifier a High Quality Preamplifier design was necessary. A discrete components topology, using + and - 24V supply rails was chosen, keeping the transistor count to the minimum, but still allowing low noise, very low distortion and high input overload margin. Obviously, the modules forming this preamplifier can be used in different combinations and drive different power amplifiers, provided the following stages present a reasonably high input impedance (i.e. higher than 10KOhm).

Main Module:

If a Tone Control facility is not needed, the Preamplifier will be formed by the Main Module only. Its input will be connected to some sort of changeover switch, in order to allow several audio reproduction devices to be connected, e.g. CD player, Tuner, Tape Recorder, iPod, MiniDisc etc. The total amount and type of inputs is left to the choice of the home constructor. The output of the Main Module will be connected to a 22K Log. potentiometer (dual gang if a stereo preamp was planned). The central and ground leads of this potentiometer must be connected to the power amplifier input.

Circuit diagram:

Parts:

R1_____________1K5 1/4W Resistor

R2_____________220K 1/4W Resistor

R3_____________18K 1/4W Resistor

R4_____________330R 1/4W Resistor

R5_____________39K 1/4W Resistor

R6_____________56R 1/4W Resistor

R7,R10_________10K 1/4W Resistors

R8_____________33K 1/4W Resistor

R9_____________150R 1/4W Resistor

R11____________ 6K8 1/4W Resistor

R12,R13________100R 1/4W Resistors

R14____________100K 1/4W Resistor

C1_____________220nF 63V Polyester Capacitor

C2_____________220pF 63V Polystyrene or ceramic Capacitor

C3_____________1nF 63V Polyester or ceramic Capacitor

C4,C7__________47µF 50V Electrolytic Capacitors

C5,C6__________100µF 50V Electrolytic Capacitors

Q1,Q2__________BC550C 45V 100mA Low noise High gain NPN Transistors

Q3_____________BC556 65V 100mA PNP Transistor

Q4_____________BC546 65V 100mA NPN Transistor

Tone Control Module:

This Module employs an unusual topology, still maintaining the basic op-amp circuitry of the Main Module with a few changes in resistor values. A special feature of this circuit is the use of six ways switches instead of the more common potentiometers: in this way, precise "tone flat" setting, or preset dB steps in bass and treble boost or cut can be obtained. Tone Control switches also allow a more precise channel matching when a stereo configuration is used, avoiding the frequent poor alignment accuracy presented by common ganged potentiometers. Six ways (two poles for stereo) rotary switches were chosen for this purpose as easily available. This dictated the unusual "asymmetrical" configuration of three positions for boost, one for flat and two for cut.

This choice was based on the fact that tone controls are used in practice more for frequency boosting than for cutting purposes. In any case, +5dB +10dB and +15dB of bass boost and -3dB and -10dB of bass cut were provided. Treble boost was also set to +5dB +10dB and +15dB and treble cut to -3.5dB and -9dB. Those wishing to use common potentiometers in the usual way for Tone Controls may use the circuit shown enclosed in the dashed box (bottom-right of the Tone Control Module circuit diagram) to replace switched controls. The Tone Control Module should usually be placed after the Main Input Module, and the volume control inserted between the Tone Control Module output and the power amplifier input. Alternatively, the volume control can also be placed between Main Input Module and Tone Control Module, at will. Furthermore, the position of these two modules can be also interchanged.

Circuit diagram:

Tone Control Module Circuit Diagram

Parts:

R1,R7___________47K 1/4W Resistors

R2_____________220K 1/4W Resistor

R3______________18K 1/4W Resistor

R4_____________330R 1/4W Resistor

R5______________39K 1/4W Resistor

R6______________56R 1/4W Resistor

R8_____________150R 1/4W Resistor

R9______________10K 1/4W Resistor

R10,R16__________6K8 1/4W Resistors

R11,R12________100R 1/4W Resistors

R13____________100K 1/4W Resistor

R14______________1K5 1/4W Resistor

R15,R21,R22______4K7 1/4W Resistors

R17,R24,R26______8K2 1/4W Resistors

R18______________3K3 1/4W Resistor

R19______________1K 1/4W Resistor

R20____________470R 1/4W Resistor

R23,R25_________12K 1/4W Resistors

R27,R28__________4K7 1/4W Resistors

C1_____________220nF 63V Polyester Capacitor

C2_______________1nF 63V Polyester or ceramic Capacitor

C3,C6___________47µF 50V Electrolytic Capacitors

C4,C5__________100µF 50V Electrolytic Capacitors

C7______________10nF 63V Polyester Capacitor

C8,C9__________100nF 63V Polyester Capacitors

Q1,Q2_________BC550C 45V 100mA Low noise High gain NPN Transistors

Q3____________BC556 65V 100mA PNP Transistor

Q4____________BC546 65V 100mA NPN Transistor

SW1,SW2_______2 poles 6 ways Rotary Switches

Simpler, alternative Tone Control parts:

P1______________22K Linear Potentiometer

P2______________47K Linear Potentiometer

R29,R30________470R 1/4W Resistors

R31,R32__________4K7 1/4W Resistors

C10_____________10nF 63V Polyester Capacitor

C11,C12________100nF 63V Polyester Capacitors

Power supply:

The preamplifier must be feed by a dual-rail, +24 and -24V 50mA dc power supply. This is easily achieved by using a 48V 3VA center-tapped mains transformer, a 100V 1A bridge rectifier and a couple of 2200µF 50V smoothing capacitors. To these components two 24V IC regulators must be added: a 7824 (or 78L24) for the positive rail and a 7924 (or 79L24) for the negative one. The diagram of such a power supply is the same of that used in the Headphone Amplifier, but the voltages of the secondary winding of the transformer, smoothing capacitors and IC regulators must be uprated. Alternatively, the dc voltage can be directly derived from the dc supply rails of the power amplifier, provided that both 24V regulators are added.

Note:

If this preamplifier is used as a separate, stand-alone device, thus requiring a cable connection to the power amplifier, some kind of output short-circuit protection is needed, due to possible shorts caused by incorrect plugging. The simplest solution is to wire a 3K3 1/4W resistor in series to the output capacitor of the last module (i.e. the module having its output connected to the preamp main output socket).

Technical data:

- Main Module Input sensitivity:

- 250mV RMS for 1V RMS output

- Tone Control Module Input sensitivity:

- 1V RMS for 1V RMS output

- Maximum output voltage:

- 13.4V RMS into 100K load, 11.3V RMS into 22K load, 8.8V RMS into 10K load

- Frequency response:

- flat from 20Hz to 20KHz

- Total harmonic distortion @ 1KHz:

- 1V RMS 0.002% 5V RMS 0.003% 7V RMS 0.003%

- Total harmonic distortion @10KHz:

- 1V RMS 0.003% 5V RMS 0.008% 7V RMS 0.01%

Source : www.redcircuits.com

Thursday, October 3, 2013

Constant Current LED Drive

This problem is not easy to solve. The solution is to maintain a small voltage across each constant current source. In this circuit, this is accomplished by REG1, the LM317L, which provides a bias of about 1.5V ±5%. Each transistor works as an emitter-follower, presenting the A6275 inputs with about 0.9V. Vled, the LED supply voltage, needs to be high enough to ensure that there will be at least 0.5V across each transistor but it is safe to allow significantly more than this and the supply need not be well regulated. The transistors can be general purpose NPN types such as BC548 and a single LM317L will easily supply a total LED current of at least 1A. A6275s are made by Allegro.

Wednesday, October 2, 2013

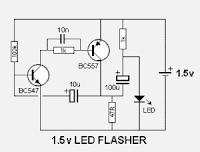

1 5V POWERED LED FLASHER ELECTRONIC DIAGRAM

It is a charge pump design. This is where a capacitor (electrolytic) is allowed to charge and is then raised higher and allowed to discharge into a load. The load sees a voltage that can be higher than the supply.

Monday, September 30, 2013

AFX Slot Car Lap Counter

IC5a and IC5b are wired as comparators, with a 2.5V reference derived from zener diode ZD1 via the 10kO and 12kO resistors. Each time the output of IC5a goes high it clocks IC1a, a 4518 BCD counter. NAND gates IC2a & IC2b provide a carry out to the other half of IC1 for a 2-digit display. More counters may be cascaded this way to provide extra digits. The BCD outputs of IC1 drive 7-segment decoders IC3 & IC4 which drive common cathode LED displays. Push-button S1 resets the counters to 00 for both tracks for the start of a new race.

Sunday, September 29, 2013

Pulse Generator

When clock pulses are applied, its Q outputs go high successively, i.e. Q0 shifts to Q1, Q1 shifts to Q2, Q3 shifts to Q4, and so on. If any one of switches S1 through S9, say, S5 (for five pulses), is momentarily depressed, pins 5 and 6 of NAND gate N2 go low, making its output pin 4 high, which fully charges capacitor C2 via diode D. At the same time, this high output of N2 enables NAND gate N3 and clock pulses come out through pin 10. These are the required number of pulses used to check our device. The clock pulses are fed to clock-enable pin 13 of IC1, which starts counting. As soon as output pin 1 (Q5) of IC1 turns high, input pins 5 and 6 of NAND gate N2 will also become high via switch S5 because high-frequency clock allowed five pulses during momentary pressing.

This high input of N2 provides low output at pin 4 to disable NAND gate N3 and finally no pulse will be available to advance counter IC1. Before the next usage, counter IC1 must be in the standby state, i.e. Q0 output must be in the high state. To do this, a time-delay pulse generator wired around NAND gate N4, resister R4, diode D, capacitor C2, and differentiator circuit comprising C3 and R5 is used. When output pin 4 of NAND gate N2 is low, it discharges capacitor C2 slowly through resistor R4. When the voltage across capacitor C2 goes below the lower trip point, output pin 11 of NAND gate N4 turns high and a high-going sharp pulse is produced at the junction of capacitor C3 and resistor R5.

This high input of N2 provides low output at pin 4 to disable NAND gate N3 and finally no pulse will be available to advance counter IC1. Before the next usage, counter IC1 must be in the standby state, i.e. Q0 output must be in the high state. To do this, a time-delay pulse generator wired around NAND gate N4, resister R4, diode D, capacitor C2, and differentiator circuit comprising C3 and R5 is used. When output pin 4 of NAND gate N2 is low, it discharges capacitor C2 slowly through resistor R4. When the voltage across capacitor C2 goes below the lower trip point, output pin 11 of NAND gate N4 turns high and a high-going sharp pulse is produced at the junction of capacitor C3 and resistor R5.This sharp pulse resets counter IC1 and its Q0 output (pin 3) goes high. This is represented by the glowing of LED. Ensure the red LED is glowing before proceeding to get the next pulse. Press any of the switches momentarily and the LED will glow. If the switch is kept pressed, the counter counts continuously and you cannot get the exact number of pulses.

Saturday, September 28, 2013

The Gentle Touch Circuit Diagram

Consumer appliances these days hardly ever have a proper mains switch. Instead, appliances are turned on and off at the touch of a button on the remote control, just like any other function. This circuit shows how a device (as long as it does not draw too high a current) can be switched on and off using a pushbutton. The approach requires that a microcontroller is already available in the circuit, and a spare input port pin and a spare output port pin are required, along with a little software. When power is applied T1 initially remains turned off. When the button is pressed the gate of T1 is taken to ground and the p-channel power MOSFET conducts. The microcontroller circuit is now supplied with power. Within a short period the microcontroller must take output PB1 high. This turns on n-channel MOSFET T1 which in turn keeps T1 turned on after the push-button is released.

Now the microcontroller must poll the state of the push-button on its input port (PB0) at regular intervals. Immediately after switch-on it will detect that the button is pressed (a low level on the input port pin), and it must wait for the button to be released. When the button is next pressed the device must switch itself of f: to do this the firmware running in the microcontroller must set the output port pin to a low level. When the button is subsequently released T1 will now turn off and the supply voltage will be removed from the circuit.

The circuit itself draws no current in the off state, and for (rechargeable) battery-powered appliances it is therefore best to put the switch before the voltage regulator. For mains-powered devices the switch can also be fitted before the voltage regulator (after the rectifier and smoothing capacitor). Since there is no mains switch there will still be a small standby current draw in this case due to the transformer. Be careful not to exceed the maximum gate-source voltage specification for T1: the IRFD9024 device suggested can withstand up to 20 V. At lower voltages R2 can be replaced by a wire link; otherwise suitable values for the voltage divider formed by R1 and R2 must be selected.

Circuit diagram:

The Gentle Touch Circuit Diagram

The Gentle Touch Circuit Diagram

The author has set up a small website for this project at http://reweb.fh-weingarten.de/elektor, which gives source code examples (which include dealing with pushbutton contact bounce) for AVR microcontrollers suitable for use with AVR Studio and GNU C. Downloads are also available at http://www.elektor.com.

Rainer Reusch - Elektor Electronics 2008

Friday, September 27, 2013

Three Hour Timer

Since Q9 is connected to the active-low EN (enable) input, the counter will now remain in this state. The charging time can be adjusted from about 2 hours 15 minutes to 4 hours 30 minutes using P1. The author set P1 to 30 kΩ, giving a charging time of 3 hours 7minutes. The greater the resistance of P1, the shorter the charging time. The timing of the circuit is not particularly precise, but its accuracy is entirely adequate for the job. When adjusting the charging time it is worth noting that the first clock cycle after the circuit is turned on (from Q0 to Q1) is longer than the subsequent ones. This is because initially capacitor C3 has to be charged to around half the supply voltage.

Since Q9 is connected to the active-low EN (enable) input, the counter will now remain in this state. The charging time can be adjusted from about 2 hours 15 minutes to 4 hours 30 minutes using P1. The author set P1 to 30 kΩ, giving a charging time of 3 hours 7minutes. The greater the resistance of P1, the shorter the charging time. The timing of the circuit is not particularly precise, but its accuracy is entirely adequate for the job. When adjusting the charging time it is worth noting that the first clock cycle after the circuit is turned on (from Q0 to Q1) is longer than the subsequent ones. This is because initially capacitor C3 has to be charged to around half the supply voltage.Wednesday, September 25, 2013

Infra Red Remote Control Tester

Circuit diagram:

Circuit diagram:COMPONENTS LIST

Resistors:

R1,R2 = 10MW

Capacitor:

C1 = 10nF

Semiconductors:

D1 = LD274 (Siemens)

D2 = LED, 3mm, low-current

IC1 = 74HC14

Miscellaneous:

Bt1 = 3V Lithium cell with solder tags, e.g.type CR2045 (560 mAh)

Tuesday, September 24, 2013

Infra red Light Barrier Using 555

The received pulses are first amplified by T1 and T2. Next comes a PLL (phase lock loop) built with the reverenced NE567 (or LM567). The PLL chip pulls its output, pin 8, Low when it is locked onto the 4.5 kHz ‘tone’ received from the transmitter. When the (normally invisible) light beam is interrupted (for example, by someone walking into the room), the received signal disappears and IC1 will pull its output pin High. This enables oscillator IC2 in the receiver, and an audible alarm is produced. The two-transistor amplifier in the receiver is purposely over-driven to some extent to ensure that the duty cycle of the output pulses is roughly 50%.

The received pulses are first amplified by T1 and T2. Next comes a PLL (phase lock loop) built with the reverenced NE567 (or LM567). The PLL chip pulls its output, pin 8, Low when it is locked onto the 4.5 kHz ‘tone’ received from the transmitter. When the (normally invisible) light beam is interrupted (for example, by someone walking into the room), the received signal disappears and IC1 will pull its output pin High. This enables oscillator IC2 in the receiver, and an audible alarm is produced. The two-transistor amplifier in the receiver is purposely over-driven to some extent to ensure that the duty cycle of the output pulses is roughly 50%. If the transmitter is too far away from the receiver, over-driving will no longer be guaranteed, hence IC1 will not be enabled by an alarm condition. If you want to get the most out of the circuit in respect of distance covered, start by modifying the value of R2 until the amplifier output signal again has a duty cycle of about 50%. The circuit is simple to adjust. Switch on the receiver, the buzzer should sound. Then switch on the transmitter. Point the transmitter LEDs to the receiver input. Use a relatively small distance, say, 30 cm. Adjust P1 on the transmitter until the buzzer is silenced. Switch the receiver off and on again a few times to make sure it locks onto the transmitter carrier under all circumstances. If necessary, re-adjust P1, slowly increasing the distance between the transmitter and the receiver.

If the transmitter is too far away from the receiver, over-driving will no longer be guaranteed, hence IC1 will not be enabled by an alarm condition. If you want to get the most out of the circuit in respect of distance covered, start by modifying the value of R2 until the amplifier output signal again has a duty cycle of about 50%. The circuit is simple to adjust. Switch on the receiver, the buzzer should sound. Then switch on the transmitter. Point the transmitter LEDs to the receiver input. Use a relatively small distance, say, 30 cm. Adjust P1 on the transmitter until the buzzer is silenced. Switch the receiver off and on again a few times to make sure it locks onto the transmitter carrier under all circumstances. If necessary, re-adjust P1, slowly increasing the distance between the transmitter and the receiver.Monday, September 23, 2013

Video Amplifier

Sunday, September 22, 2013

Master Slave Switch

All of the triac drive circuitry (including optical coupling) is integrated on-chip so there are very few external components and no additional power supply necessary. This makes the finished design very compact. Diodes D1, D2, D3 and D4 perform the current sensing function and produce a voltage on C2 when the master equipment is switched on. A Schottky diode is used for D5 to reduce forward voltage losses to a minimum. The circuit is quite sensitive and will successfully switch the slave even when the master equipment draws very little mains current. The RC network formed by R1 and C1 provides some protection for the solid-state relay against mains-borne voltage transients.

Warning:

This circuit is connected to the mains. it is important to be aware that the chip has lethal voltages on its pins and all appropriate safety guidelines must be adhered to! This includes the LED, for safety it must be fitted behind a transparent plexiglass shield.

Friday, September 20, 2013

1994 Saturn sedan 1 9L Wiring Diagram

|

| 1994 Saturn sedan 1.9L Wiring Diagram |

Wednesday, September 11, 2013

4A High Speed Low Side Gate Driver Circuit

- Low-Cost, Gate-Driver Device Offering Superior Replacement of NPN and PNP Discrete Solutions

- Pin-to-Pin Compatible With TI’s TPS2828 and the TPS2829

- 4-A Peak Source and 4-A Peak Sink Symmetrical Drive

- Fast Propagation Delays (17-ns typical)

- Fast Rise and Fall Times (8-ns and 7-ns typical)

- 4.5-V to 18-V Single Supply Range

- Outputs Held Low During VDD UVLO (ensures glitch free operation at power-up and power-down)

- CMOS Input Logic Threshold (function of supply voltage with hysteresis)

- Hysteretic Logic Thresholds for High Noise Immunity

- EN Pin for Enable Function (allowed to be no connect)

- Output Held Low when Input Pins are Floating

- Input Pin Absolute Maximum Voltage Levels Not Restricted by VDD Pin Bias Supply Voltage

- Operating Temperature Range of -40°C to 140°C

- 5-Pin DBV Package (SOT-23)

- Switch-Mode Power Supplies

- DC-to-DC Converters

- Companion Gate Driver Devices for Digital Power Controllers

- Solar Power, Motor Control, UPS

- Gate Driver for Emerging Wide Band-Gap Power Devices (such as GaN)

Tuesday, September 10, 2013

Wednesday, September 4, 2013

IR Remote Control Extender Mark 3

IR appliances use pulses (control signals) sent over a modulated IR carrier wave. The carrier wave may be modulated at various frequencies, 36-38KHz being the most popular.Some Satellite receivers use even higher frequencies than this. The IR1 remote module receives an infra red signal and separates control pulses from the modulation. To re-transmit, a 555 timer is configured as an astable oscillator. The 555 timer is controlled by the signal on the reset pin, high generating a carrier and low no carrier. Each control pulse turns on the oscillator for the duration of a logic high signal and off for a logic 0 signal, thereby creating a newly modulated IR signal. The IR module, part number IR1 is available from Harrison Electronics in the UK, IR1 may not be listed in their catalogue but if you ask for an IR1, they will send you the correct part. The IR1 arrives in a small aluminium case, the connections viewed from underneath are shown below:

Infra Red Module, IR1 Pinout

Parts List:

C1 100u 10V

C2 100n polyester

C3 120p silver mica

C4 100n polyester

R1 150k

R2 2k2k

R3 1k

R4 47R 1W

Q1 BC109C

IC1 LM7805

IC2 555

IC3 IR1 module from Harrison Electronics or TSOP1838

IC4 4049 CMOS Invertor LED1 Red LED (or any visible colour)

LED2 TIL38 or part YH70M from Maplin Electronics

PCB Layout (courtesy of Claudio from Italy):

First the component side of the board is shown below.

.png)